The COSMEC project (Cold Spray of Metal-to-Composite - 2017N4422T), funded through the 2017 PRIN call by the Italian Ministry of Education, Universities and Research (MUR) under the young researchers’ program, has officially concluded. The project involved the University of Salerno (Principal Investigator), the University of Naples Federico II, and Politecnico di Milano. The research unit from the Department of Mechanical Engineering was composed of Professor Chiara Colombo, Professor Sara Bagherifard and Dr. Asghar Heydari Astaraee.

The COSMEC project employed the innovative cold spray technique for depositing powders and generating metallic coatings on polymeric substrates. This technique involves accelerating powders at supersonic speeds, utilizing kinetic energy and plastic deformation to achieve strong adhesion. As the powders are not melted, this technique is particularly prone to functionalize polymeric materials and polymer matrix composites (metallization), enabling thermal and electrical conductivity of the substrate, and enhancing wear and erosion properties.

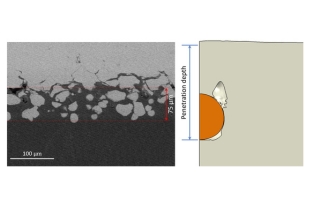

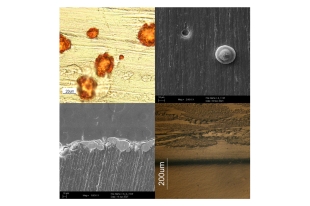

The research unit at DMEC actively participated in both experimental and numerical activities outlined in the project, collaborating closely with the partners. From the experimental side, using the high-pressure cold spray unit at the DMEC laboratories, the team analyzed and optimized manufacturing parameters on pure polymer (PEEK - Polyether ether ketone) coated with copper powders, as well as on composite material (epoxy matrix reinforced with glass fiber) coated with aluminum powders. This latter application required a customized production process developed by other involved research units to incorporate a thin surface layer of thermoplastic polypropylene. This approach was necessary because the thermosetting epoxy resin was not suitable to accommodate the accelerated particles, which would have caused erosion and damage to the substrate.

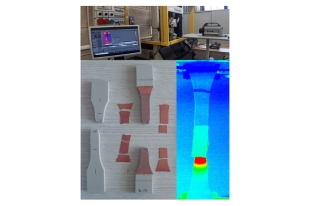

The coated materials were investigated through hardness tests, high-resolution microscope analyses, and static load applications to highlight progressive loss of adhesion between the polymer and the particles, particularly critical at the initial deposited state, as well as cohesive damage within the metallic coating itself. These cohesive properties were also investigated using the small punch test, a recently standardized static test applying bending loads to small discs of the cold-sprayed material.

Throughout all experimental activities, infrared thermographic monitoring was employed. Specifically, it was used during manufacturing to monitor the actual substrate temperature during the particle flow, a critical parameter for ensuring adhesion. Pulsed active thermography tests were conducted to identify pre-existing defects in the coated layer after manufacturing, such as porosities, cracks, or delamination. Finally, thermography was used for the thermal monitoring during static tensile tests, allowing for estimations of the fatigue limit and the cohesive strength in accordance with other mechanical tests conducted.

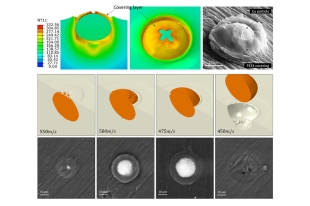

In parallel to the experimental activities, a detailed numerical modeling of the impact of a single particle on the substrate was implemented to understand the anchoring and adhesion mechanisms. The simulations were implemented through explicit analyses based on the finite element method, utilizing a coupled Lagrangian-Eulerian approach to focus on the creation of the first layer in contact with the polymer. The analyses enabled a careful study of particle interlocking and highlighted its sensitivity to impact velocity and substrate temperature. The numerical results facilitated the selection of a critical velocity and an appropriate substrate temperature to optimize the adhesion process and choose manufacturing parameters, minimizing experimental coating trials.

The excellent results achieved within the COSMEC project expanded the applicability of the cold spray from the traditional metallic surface coating (metal on metal) to functionalizing polymeric surfaces (metal on polymer), optimizing spray parameters for these specific applications. Moreover, the work shed light on the adhesion mechanism between metallic particles and polymeric substrates, paving the way to innovative applications of metallization and functionalization of composite materials subjected to mechanical, thermal, and electrical loads.

The COSMEC project resulted in 3 publications in indexed journals, 3 presentations at national conferences, and 5 at international ones, as well as 3 master's theses. Additionally, the COSMEC project facilitated interactions and connections with various international groups working in the field of cold spray, providing the foundation for further collaborations and the development of innovative projects.