Archès

Website's ProjectArchès

Website's Project

At Archès Lab (ARChitected HEterogeneous Structures Laboratory) we implement theoretical, numerical and experimental approaches for design, development, characterization of multifunctional architected heterogeneous structures for various applications including aerospace, automotive and biomedical. Our mission is to establish a distinctive and interdisciplinary research and educational program aimed at identifying, understanding and manipulating the process-structure-property linkage in heterostructured materials. We strive to address scientific challenges in this area and provide tailored material and structural solutions that deliver exceptional performance.

INSTRUMENTS & FACILITIES

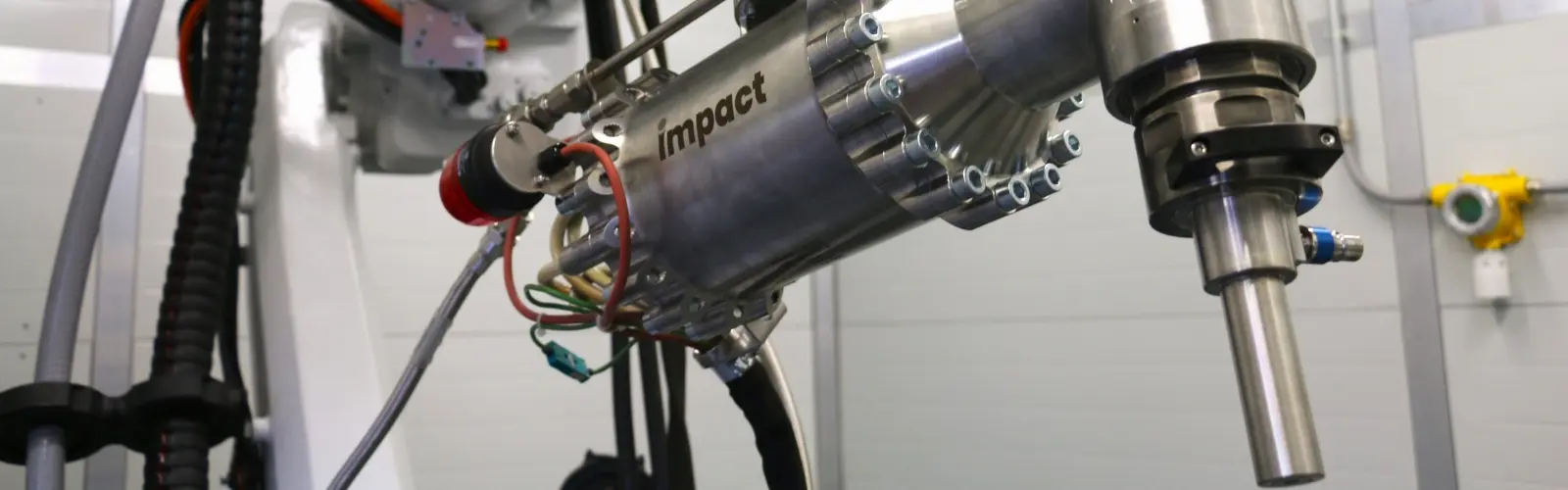

- We are users of the high pressure Cold Spray system (Impact Innovations 6/11) equipped with ABB IRB4600 Robot installed at the DynAM Lab (DMec)

- K&W material in/ex-situ testing substage for tensile, compressive, three- and four-point bending loading conditions

- Anton Paar's Step 501 Micro and nano-mechanical testing platform for hardness, elastic modulus, splat and coating adhesion, scratch resistance, and many other customized surface mechanical characterizations

- Mini FP2 desktop machine for high-cycle fatigue testing of mini-specimens

- SONAT Ultrasonic shot peening machine

- HiWatch HR2 Particle analyzer for accurate particle size, velocity, and plume density measurement, used for cold spray process monitoring

ACTIVITIES

Our research is multidisciplinary and focuses on materials and structures with various types of heterogeneity focusing on the following key research themes:

Chemical heterogeneity

- Using Cold Spray to simultaneously deposit a variety of materials, resulting in deposits with distinct zones exhibiting diverse properties

- Enhancing and fine tuning performance and functionality

Microstructural heterogeneity

- Mixing different volume fractions of micro and nanocrystalline powder particles to obtain bimodal structures with heterogeneous arrangement of crystalline phases

- Exploring different strategies to exploit the potential of cold spray in modulating the mechanical properties of the deposits

Geometrical heterogeneity

- Leveraging heterogeneity to design architected structures with customized structural performance

- Pairing numerical analysis, machine learning algorithms, and experimental tests

Shape control in solid-state additive manufacturing

- Accurately predicting the shape of cold sprayed deposits and its correlation to working parameters

- Combining physics-based and machine learning approaches to develop comprehensive and computationally efficient shape prediction models adaptable for additive manufacturing and repair applications

Post-processing and surface functionalization

- Using mechanical surface treatments such as ultrasonic shot peening to selectively impact the surface of a substrate, creating hybrid microstructures on the surface and along the depth of the substrate material

- Inducing grain size heterogeneity in thin structures to modulate their mechanical response