LaST - Laboratory for Safety of Transport systems

LaST - Laboratory for Safety of Transport systems

The Laboratory’s main activities involve testing and modelling of vehicle systems with emphasis on suspension systems, tyres, braking systems, drivelines for both conventional or electric vehicles. Key performance aspects such as NVH, durability, thermal and mechanical performances are derived either experimentally or through numerical simulations. Measurement of the parameters which affect the vehicle dynamics (e.g. vehicle inertia properties) is performed by original and dedicated test rigs. Patented load cells and measuring hubs are available. The measurement and simulation of vehicle ride comfort are among the Laboratory's key competencies, along with access to the DRISMI dynamic driving simulator The main activities include testing vehicle components and the driver’s or vehicle occupant’s perception, measurement of the driver’s psychological status (drowsiness, distraction),co-simulation of complex traffic conditions with SUMO in the loop And response of vehicle-and driver to external disturbances.

INSTRUMENTS & FACILITIES

- InTenso test rig: measurement of the mass properties of full vehicles

- InTensino test rig: measurement of the mass properties of rigid bodies up to 400 kg

- RuotaVia test rig: twin drum providing a rolling contact surface for tyre or suspension or driveline test and development

- Measuring hubs: measurement of the forces acting at the tyre contact patch

- (Special patented) 6 axis load cells: measurement of forces for NVH or durability purposes

- MaRiCo Dummy: objective measurement of the ride comfort of vehicles.

- BRAD: measurement of the forces acting both at the brake and at the tireground interface

- VeTyT (Velo Tyre Test rig) for the mechanical characterization of bicycles tyres

- Moving laboratory (MoLAS) for tire and suspension and automotive components testing

- DriSMi - dynamic Driving Simulator

ACTIVITIES

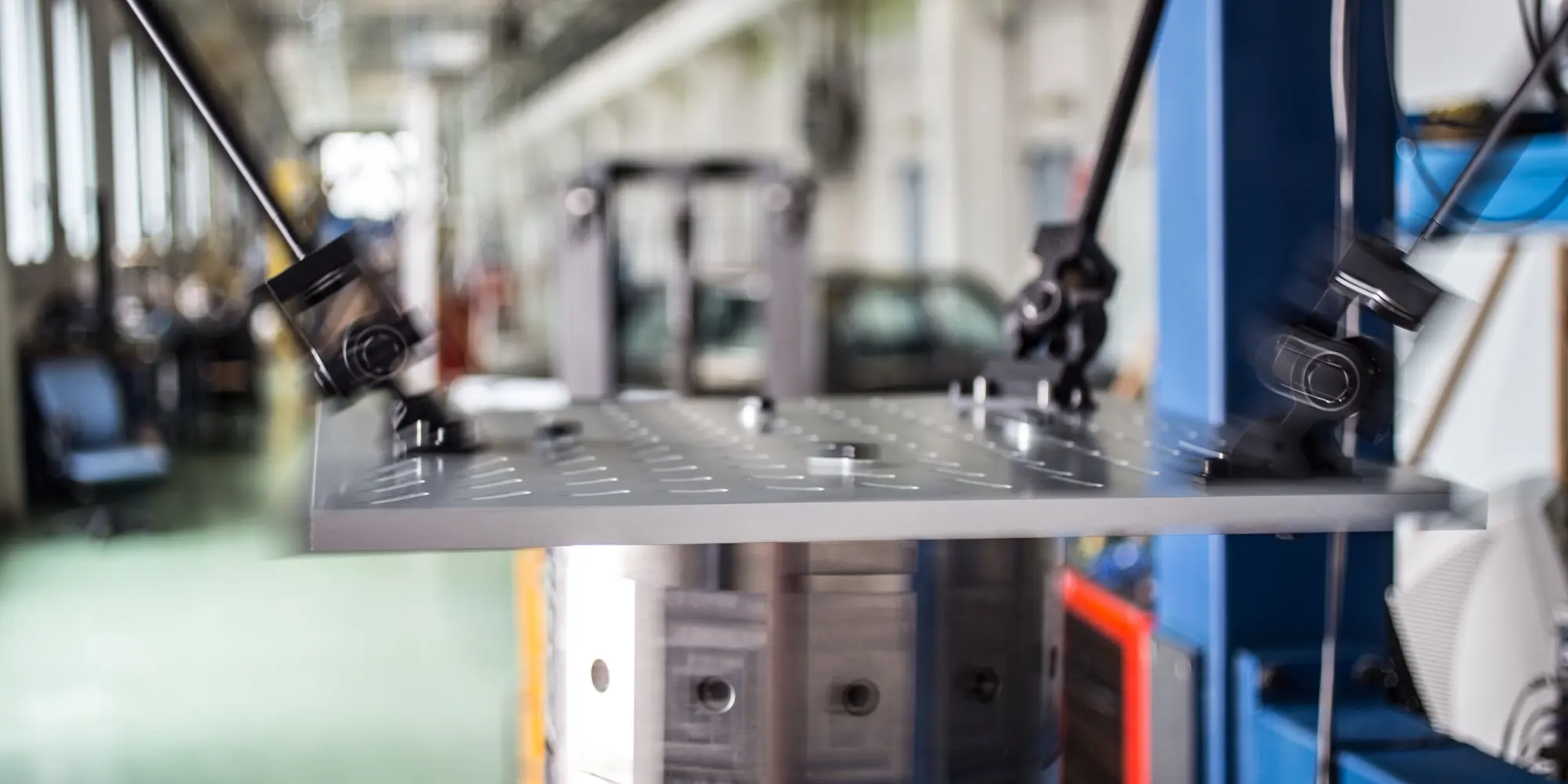

InTenso+ and InTensino+

Measurement of the Centre of Gravity location of full vehicles (InTenso+) or vehicle components (InTensino+).

The test rigs are composed by a ‘carrying system’ (a steel cage or a plank), which bears the body under test; three rods connect the carrying system to an external fixed frame. The rods are connected to the frame and to the carrying system by low-friction Hooke joints. A load cell is fitt ed on each rod. The orientation of the rods is measured by means of 6 absolute 17 bit encoders positioned on the upper Hooke joint. The Centre of Gravity location and the Inertia Tensor are computed knowing the angular acceleration of the carrying system and the forces acting on it.

MoLAS

The MoLAS is semi-trailer for indoor/outdoor tire characterization under realistic tyre-road grip condition. The vertical load on the tyre is controlled by means of a pneumatic spring actuator. A double-stage suspension system allows to filter the vertical disturbance induced by road irregularity. Lateral force is applied by means of two electric actuators that allow precisely control steering and camber angles. The wheel steering axis falls exactly in the meridian (mid) plane of the wheel and this condition happens for any possible value of camber angle. Tire forces and moments are measured by an innovative six-axis force sensor specifically designed for the MoLAS. The MoLAS can test the tyre both in traction or braking conditions. This is achieved by a high-power engine or a retarder brake.

Measuring wheels/hubs

Measurement of the forces acting at the tyre contact patch, custom design.

The measuring hubs are based on a statically determined three cantilever/spoke structure replacing the wheel center. Strain gauges are fitted on each spoke. The statically determined connection consists of three spherical joints with an additional degree of freedom along the axis of the spokes. A telemetry system has been designed and employed to transmit the force signals to a data storage unit.

Instrumented Steering Wheel

The Instrumented Steering Wheel can measure the forces and the moments applied by the driver at each hand. The ISW has a carbon fiber composite structure and is equipped with two special six-axis load cells. Six force transducers are placed inside the handles to detect the grip forces exerted by each hand.

MaRiCo Dummy

- Objective measurement of vehicles ride comfort.

- Comparison between different seats.

The dummy can reproduce the vertical and longitudinal accelerations at the body-seat interfaces that would be respectively sensed by a human subject. It can be adjusted to simulate different human subjects, from 5 percentile to 95 percentile, and to accommodate to different seats configuration. The dummy has a vibrating mass moving along the spine axis. An adjustable magnetic damper controls the motion of such a mass.

VeTyT

- Measurement of lateral force

- Measurement of self-aligning torque

The VeTyT can be employed to test a wide range of bicycle tyres with different wheel sizes, from 16” to 29” diameter. The system consists of a rigid frame that allows a wheel to be steered and cambered. Tests can be performed either on a drum or on a flat surface.

BRAD

The test bench is composed by a rotating steel drum, which provides a rolling contact surface for a pneumatic tire. The brake under test in connected to the pneumatic tyre spindle. The vertical load is applied to the wheel and brake by means of a pneumatic spring. A two-stage flywheel configuration has been chosen. The test rig can be used to study the interaction between brakes and tires near wheel locking.

RuotaVia

- Design and testing of tyres

- Design and testing of suspension systems

- Design and testing powertrains

- NVH measurements

The RuotaVia rig is composed by a horizontal axis steel drum, providing a running contact surface for heels. An asynchronous motor+neuro controlled inverter drives the drum up to 400 km/h.