Material Analysis

Material Analysis

The laboratory is equipped with state-of-the-art analytical instruments and testing devices for the investigation of material properties. Optical and electron microscopes equipped with EDX and EBSD detectors are available for microstructure, texture and failure analysis. A range of analytical instruments is used to characterize thermal, physical and chemical properties of materials, including a dilatometer, a laser-flash analyzer, a differential scanning calorimeter, an optical emission spectrometer, an oxygen and nitrogen analyzer and a platform for the analysis of thermoelectric properties of materials. Properties of material surfaces and coatings can be investigated using a pin-on-disk tribometer, a scratch tester, and an instrumented microhardness tester.

INSTRUMENTS & FACILITIES

- Zeiss Sigma 500 Field Emission Scanning Electron Microscope equipped by the Oxford Ultimax 65 Energy Dispersive X-ray Analysis (EDS) and the Oxford C-NANO Electron Backscattered Diffraction (EBSD) detectors

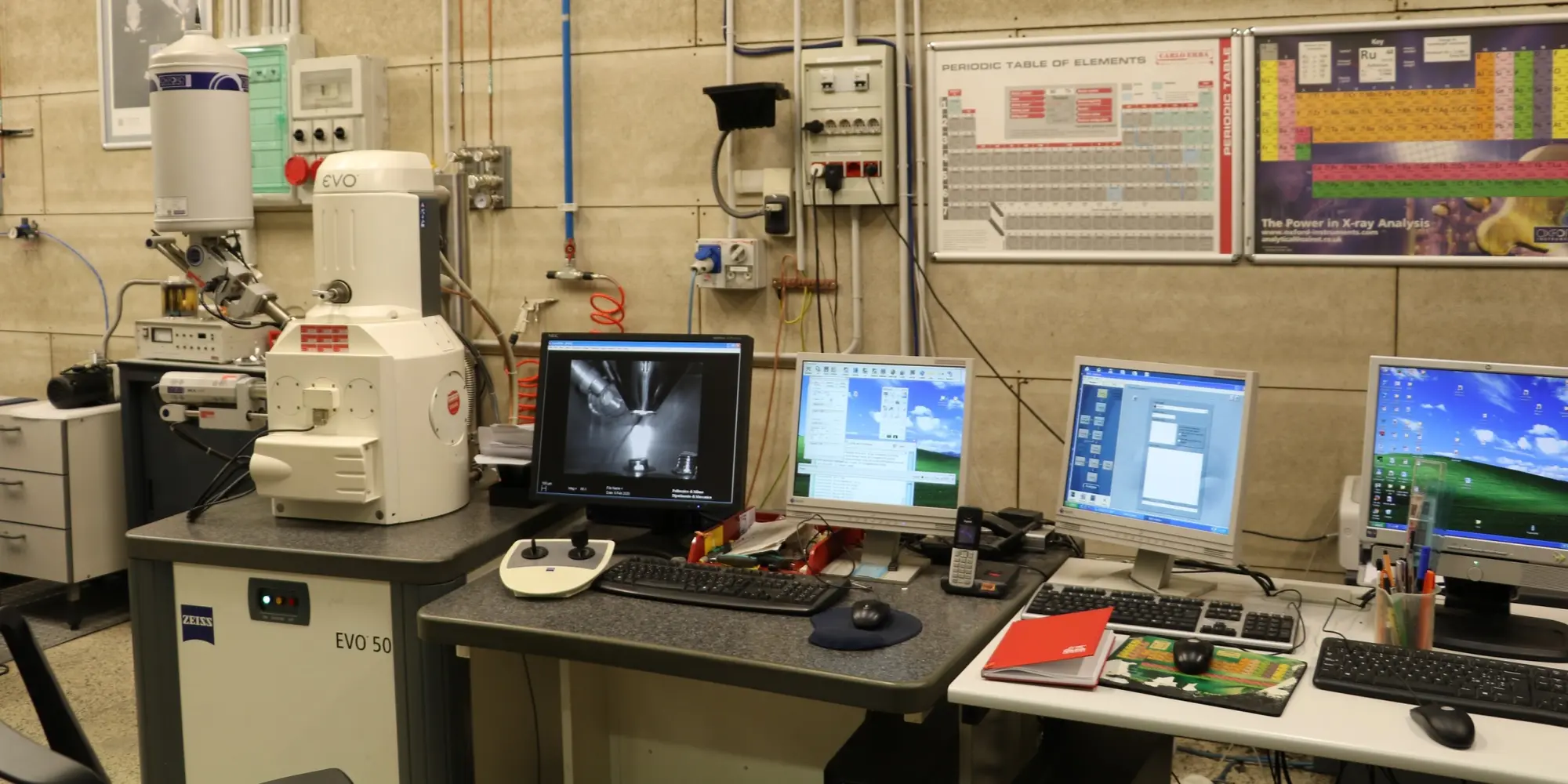

- Zeiss EVO 50XVP Thermionic Scanning Electron Microscope with the Oxford Inca Energy 200 X-ray microanalysis (EDS) detector

- Nikon Eclipse LV150NL light optical microscope

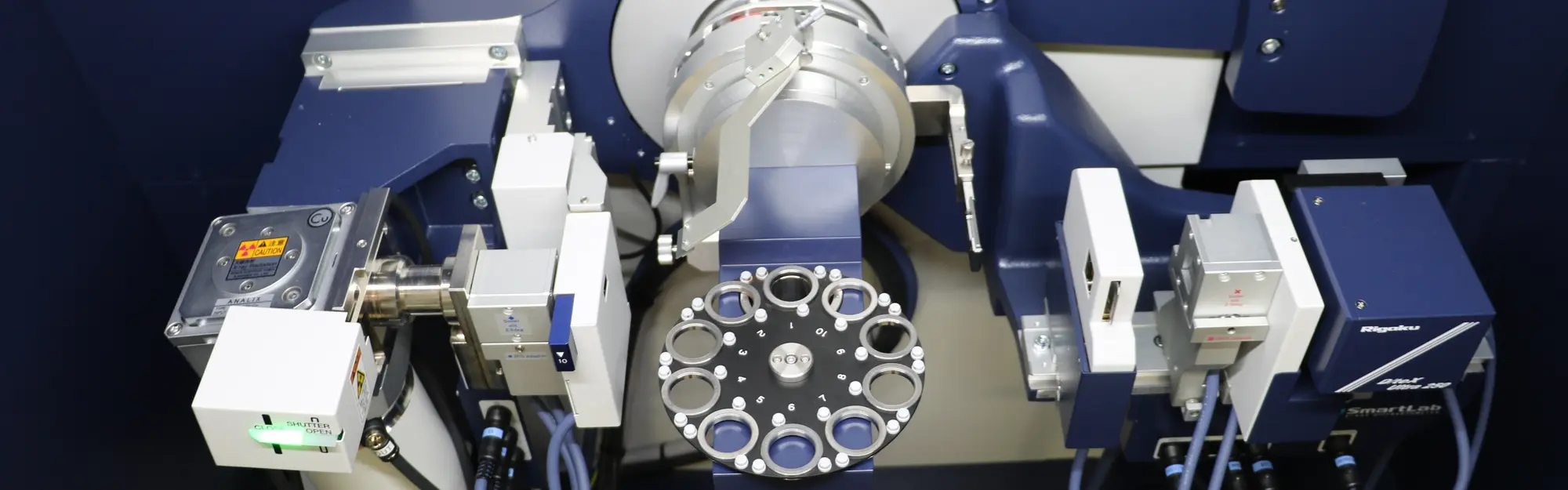

- Rigaku SmartLab SE powder X-Ray diffractometer for qualitative and quantitative phase analysis. The instrument is equipped with a Eulerian cradle for stress and texture analysis of crystalline materials by EBSD and XRD

- StressTech X3000 X-Ray diffractometer for nondestructive measurement of residual stresses and retained austenite in crystalline materials

- It also allows analysis of large mechanical components including in-situ applications, eg. pipelines and bridges

- Setaram Themys One DSC / TGA thermal analysis system equipped with furnace and rods for temperature cycles of up 1600°C

- OES Bruker Q4 Tasman 130

- Matrixes: Fe, Al, Ni, Ti

- Bulk samples

- Minimum sample size = 25x25x0.5 mm

- LECO Oxygen and Nitrogen analyzer

- Vertical Dilatometer Linseis V75 with temperature ranges RT-900°C and RT 1600°C

- Laser Flash Analyzer Linseis LFA 1000/1600 for direct measurements of thermal diffusivity and indirect measurements of thermal conductivity in the temperature range RT-1600°C

- Seeback/TE Linseys LZT 1100

- Combined LFA (thermal diffusivity) and LSR (Seebeck and resistivity) for cylindrical (up to 6 mm in diameter and max 23 mm long), prismatic (2 to 5 mm rectangular and max. 23 mm long) and butt on-shape (from Ø12.7 to Ø25.4 mm) samples

- Maximum temperature 1100 °C under He atmosphere

- CSM pin-on-disk tribometer

- CSM Microindenter instrumented microhardness (loads from 0.01 to 10 N) and scratch tester (load range 0.3 30 N)

- Foerster SIGMATEST 2.069 Eddy Current instrument that measures the electrical conductivity of non-ferromagnetic metals in the range of 0.5 to 65 MS/m. Foerster Sigmatest eddy current instrument that measures the electrical conductivity of non-ferromagnetic metals electrical resistivity measurements

- Heat flow probes, specifically the high-temperature FCR-200-M-K supplied by Wuntronic GmbH, with max service temperature 550°C and max heat flux range 15,800 W/(m2K), sensitivity 560 (W/m2)/mV

- Multimeter 7.5 digits Keithley

ACTIVITIES

- Microstructure investigation, failure analysis and quality control by optical and scanning electron microscopy

- Texture analysis of crystaline materials by EBSD and XRD

- Chemical analysis by OES, EDX and LECO

- Analysis of phases and residual stresses by X-ray diffraction

- Thermal analysis by dilatometer, laser flash analyzer and differential scanning calorimetry

- Wear tests by pin on disk tribometer and analysis of coating adhesion by scratch tester