A sustainable, FBS-free cultivated meat via 3D bioprinting

The CELLtoFOOD project, funded by PRIN 2022, involves three Italian institutions - University of Milan, Politecnico di Milano and University of Palermo - in crafting an open-access, sustainable protocol for producing cultivated meat and seafood. Its most ambitious aim is to eliminate fetal bovine serum (FBS), the current gold standard for cell nutrition yet unsustainable ethically and environmentally.

CELLtoFOOD focuses on formulating culture media from plant-based ingredients and food-industry by-products, reducing waste and costs. By valorizing dairy and fishery residues, the project supports circular-economy principles and UN Sustainable Development Goals, drastically cutting water, land use, and CO₂ emissions compared to conventional livestock farming.

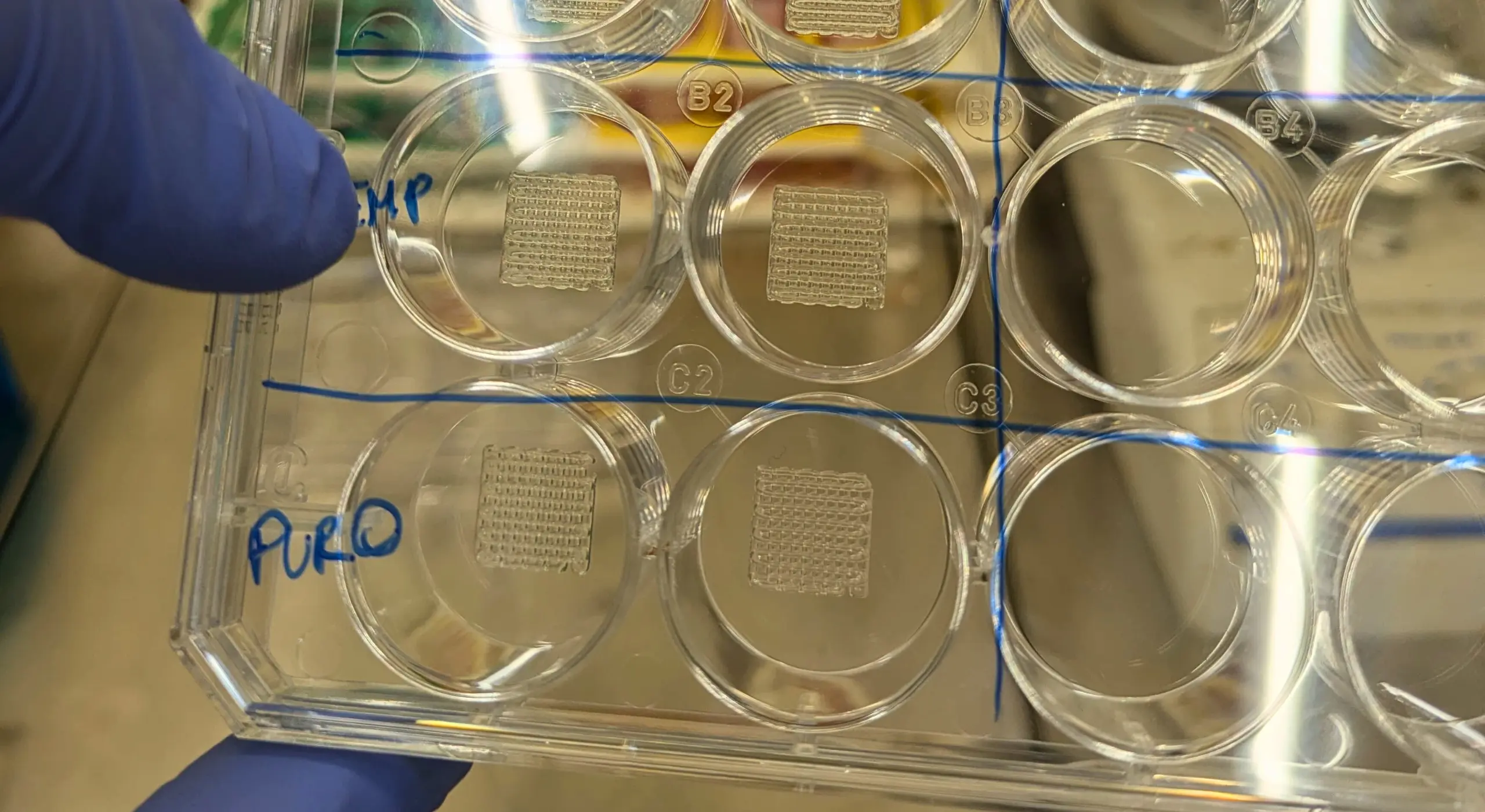

Extrusion-based 3D bioprinting deposits alternating layers of bio-ink and cells in predefined patterns, optimizing oxygenation and nutrient distribution. With precise control of pressure, speed, and temperature, the method achieves high dimensional fidelity and ideal microenvironments for cell proliferation, leading to final products mirroring meat or fish tissue.

Politecnico di Milano leads the feasibility study of 3D bioprinting in three areas:

- Mechanical design and testing of alginate-gelatin scaffolds with hemp-protein additives for optimal strength and porosity.

- Process parameter optimization, employing in-situ monitoring to refine extrusion pressure, print speed, and thermal settings.

- Multicellular bioprinting, integrating pneumatic and inkjet heads to co-print myoblasts and adipocytes.

Through embedded sensors and automated image analysis, DMEC guarantees reproducible, scalable processes, paving the way for pilot-scale, industrial-level production.