Advanced Cooling for High-Power Electronics through New Materials and 3D Printing

Development of metallic interlayers and LPBF processing to directly integrate high-performance cooling systems onto silicon substrates

COMET (Novel interlayer alloys for bonding high-conductivity metals to silicon using Laser Powder Bed Fusion) has been recently and successfully completed. The project was funded by the European Space Agency (ESA) and coordinated by Politecnico di Milano under the supervision of Prof. Riccardo Casati, in collaboration with the University of Twente. COMET addressed one of the most critical challenges in the field of thermal management for high-power electronic devices: the direct and reliable integration of metallic cooling systems onto silicon substrates.

The continuous increase in power density in modern electronics, particularly in space and aeronautical applications, imposes unprecedented requirements on thermal management solutions. Efficient heat dissipation is essential to ensure device reliability, lifetime, and performance under extreme operating conditions. Conventional cooling architectures typically rely on thermal interface materials (TIMs), adhesive layers, or mechanical fastening systems. While widely used, these approaches introduce additional thermal resistances, reduce heat transfer efficiency, and may degrade over time due to thermal cycling, mechanical stresses, or harsh operating environments.

COMET proposed a radically innovative solution to overcome these limitations by eliminating such interfaces altogether. The project explored the additive manufacturing of metallic heat sinks and cooling structures directly onto silicon substrates using Laser Powder Bed Fusion (LPBF) technology. This approach has the potential to create highly efficient thermal pathways between the heat source and the cooling system, significantly enhancing the overall thermal performance of the device.

At the core of the project was the development of novel metallic interlayer alloys capable of acting as a thermal bridge between silicon and high-thermal-conductivity metals, such as aluminium, which is commonly used in heat exchanger manufacturing. These interlayers were designed to ensure thermodynamic stability and chemical compatibility, while mitigating issues related to the mismatch in thermal expansion coefficients between silicon and aluminium, the formation of brittle intermetallic phases, and crack initiation during processing.

The consortium adopted an integrated and multidisciplinary approach, combining thermodynamic modelling, alloy and metal powder design, LPBF process development, and advanced material characterization. Mechanical behaviour, microstructural evolution, and the metallurgical quality of the metal–silicon interface were systematically investigated, successfully demonstrating the feasibility of producing robust, crack-free metal/silicon joints with promising thermal and mechanical performance.

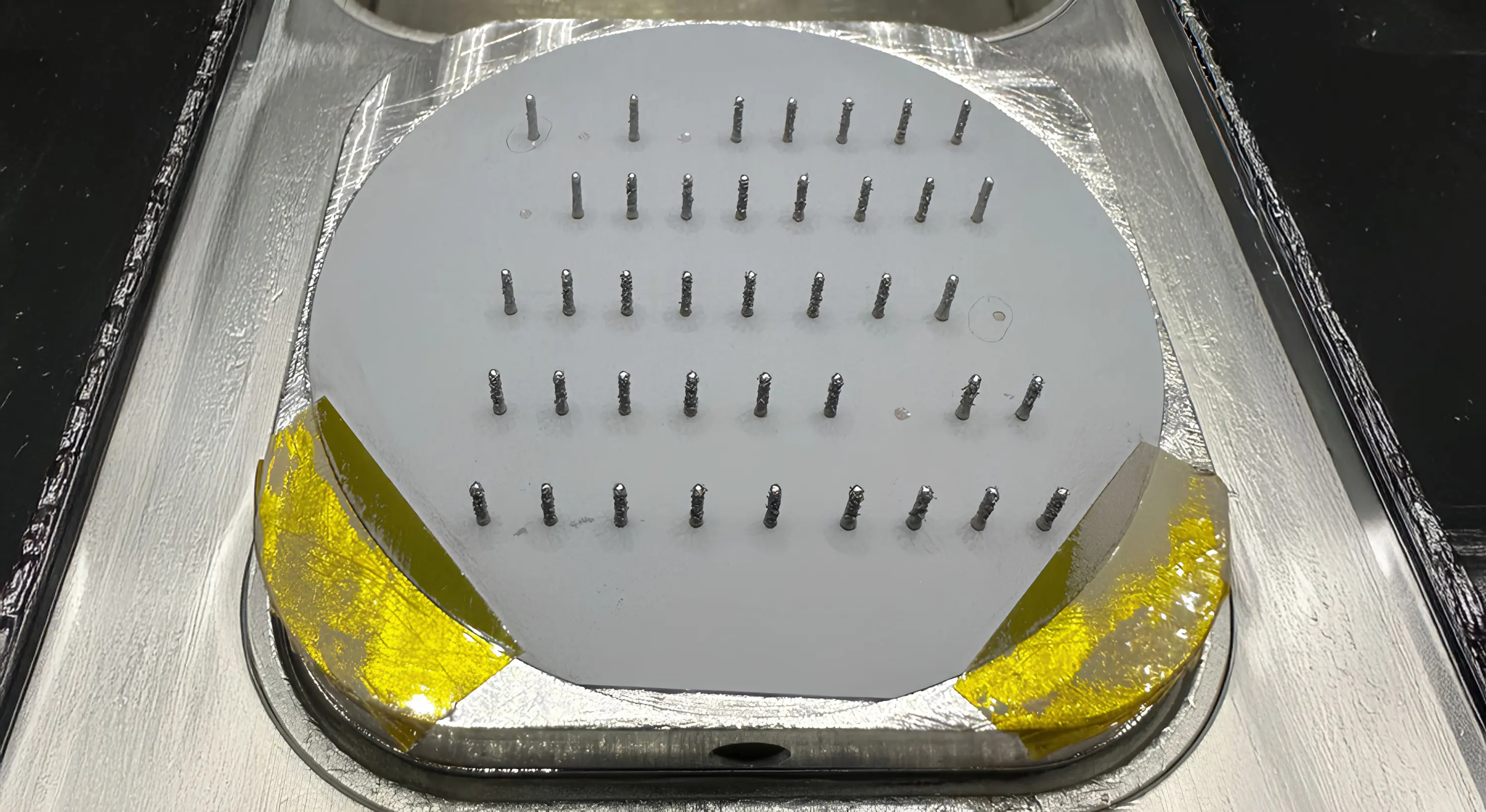

In the final phase of the project, a proof-of-concept demonstrator was also developed. Complex micro-cooling structures, featuring intricate geometries enabled by additive manufacturing, were printed directly onto silicon wafers, highlighting the design freedom and functional integration offered by the proposed approach. Overall, COMET has established a solid scientific and technological foundation for future developments aimed at industrial exploitation. Beyond space electronics, the project outcomes open new opportunities for a wide range of applications, including data centers, electric vehicles, power electronics, and advanced energy systems, where efficient, compact, and reliable thermal management represents a key enabling factor.