Circular Food System Lab: circular and digital innovation for the future of food systems

Advanced technologies and interdisciplinary research for the circular transition of agri-food systems

Its activities are particularly aligned with the Farm to Fork Strategy promoted by the EU Green Deal 2020, which aims to support the ecological transition of agri-food systems and the development of sustainable and safe supply chains throughout all stages, from production to processing and distribution, including related services such as hospitality and catering. The strategy also promotes the consumption of sustainable foods, the shift toward healthy dietary habits, the reduction of waste, the fight against food fraud, and the protection of biodiversity in food systems.

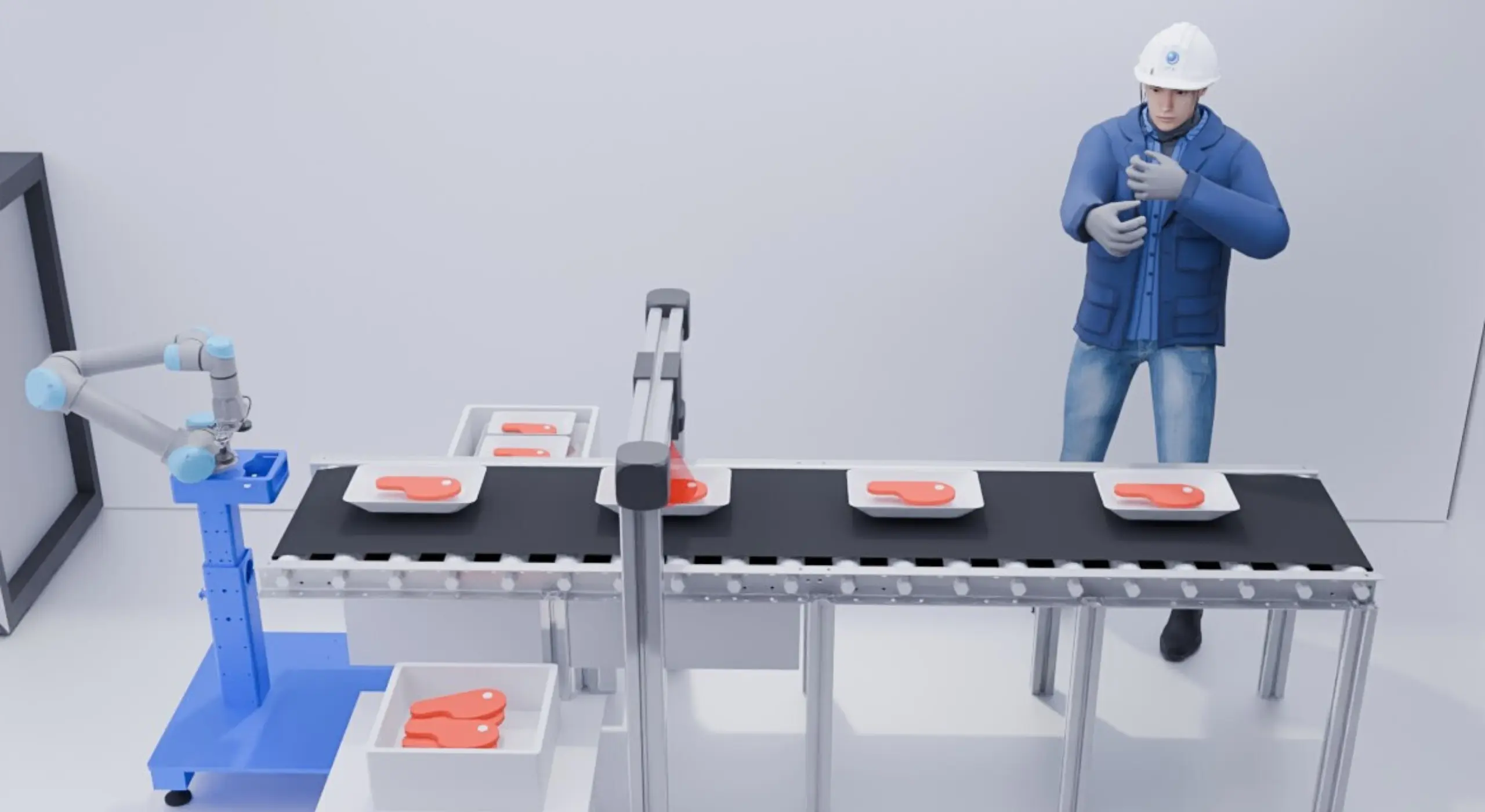

The laboratory is organized into three modules. The Department of Mechanical Engineering coordinates the “Recovery and Recycling for Food System” module under the scientific leadership of Professor Giorgio Colombo. Within this initiative, the research group he leads focuses on the recovery, identification, sorting, and treatment of post-consumer materials related to food systems. In this context, a prototype station has been developed for studying and simulating the (de-)packaging of food packaging. The station integrates a Universal Robot UR5 collaborative robot, an environmental tracking system, and immersive visualization solutions. The laboratory is a hybrid environment where each physical element has a digital counterpart, enhancing the ability to simulate real production environments and deeply analyze human-machine interactions.

The entire area is tracked by a system composed of 16 cameras: 8 Vicon cameras dedicated to tracking rigid bodies with markers and 8 markerless cameras for real-time tracking of up to 5 human operators simultaneously, without the need for markers and with the ability to detect detailed movements such as hand and finger poses. The station also features a food quality identification system based on computer vision and odor recognition technologies. This system, developed in-house using a multimodal artificial intelligence approach, is capable of identifying the type of food on the line and its level of spoilage. Integrated with the robot, it allows automatic sorting operations based on the detected conditions. The operator can intervene and interact using XR systems that provide contextual information and enable immersive control of the entire depackaging line.

The laboratory’s virtualization capabilities are supported by a 2x3 meter stereoscopic projection screen and Meta Quest 3 headsets. CFS Lab represents a unique facility capable of integrating robotics, advanced tracking, artificial intelligence, and immersive technologies within a real-digital environment focused on sustainability. The laboratory is open to collaborations with companies, institutions, and communities to co-design innovative solutions for the future of food systems.