STELLAR: Advancing Sustainable Li-Metal Anode Production for Next-Generation Batteries

DMEC leading the development of precision laser micro-cutting under controlled atmospheres for high-performance lithium-metal anodes

The STELLAR project (Safe, sustainable, and high-throughput production of reliable lithium metal anodes for gen 4b/4c/5 batteries) addresses a critical technological challenge in the EU’s pursuit of energy sovereignty and sustainability: the industrialisation of high-performance lithium-metal (LiM) anodes for emerging solid-state (Gen 4b/4c) and lithium-sulphur (Gen 5) batteries. These technologies are pivotal for enabling safer, longer-lasting, and more energy-dense storage systems, which are essential to support Europe’s green transition and clean mobility targets.

STELLAR focuses on the development of a novel, roll-to-roll (R2R) physical vapour deposition (PVD) process for producing high-purity, ultra-thin, dense, and stable LiM anodes at industrial scale and competitive cost. The project builds on existing infrastructure at AVESTA, and advances it through several innovations: optimisation of thermal evaporation and in situ sputtering of chemically engineered protective coatings; upgrade of production equipment; implementation of advanced inline, non-destructive monitoring of thickness and roughness; and full automation of quality control using data science and machine learning.

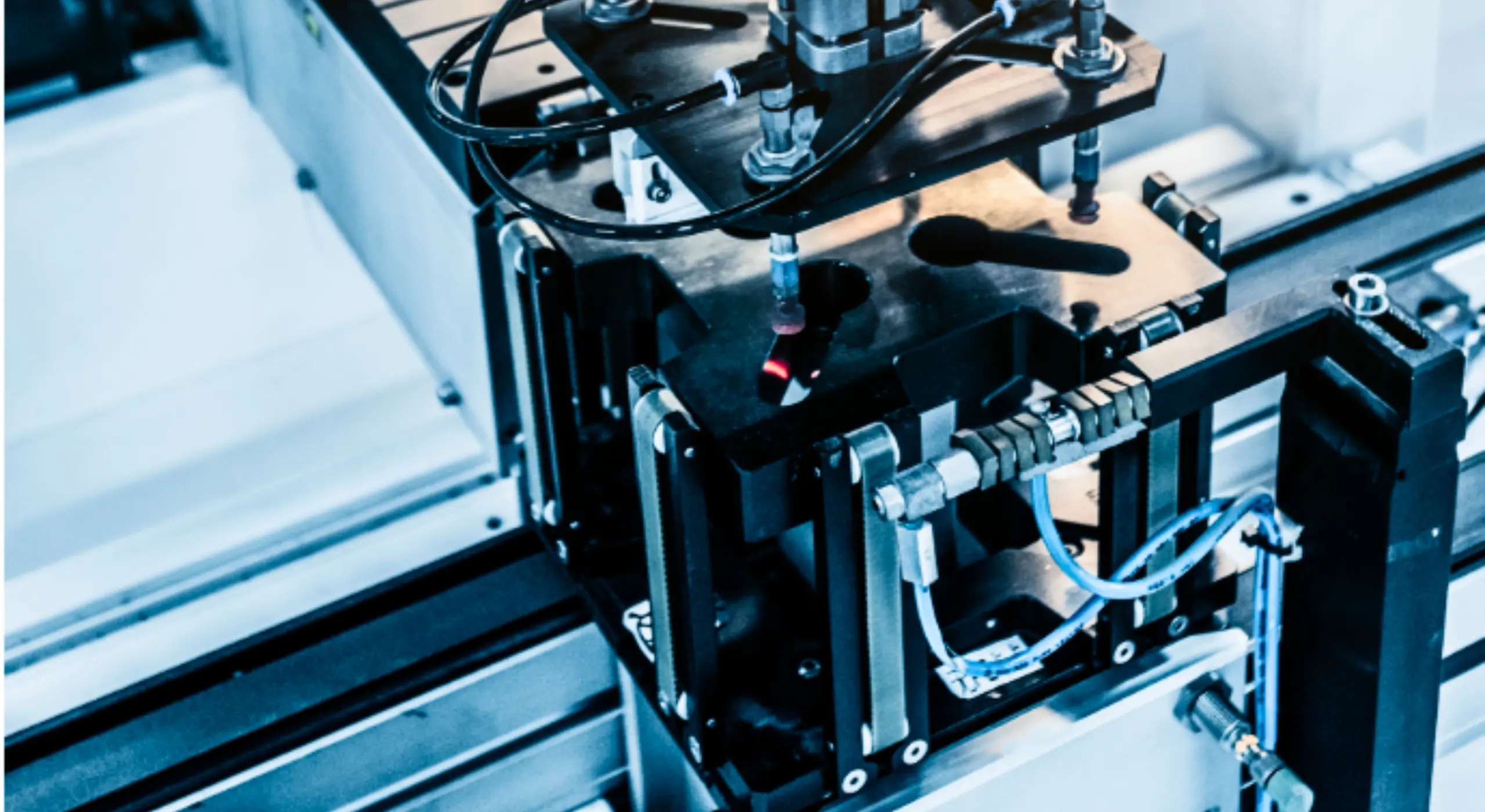

Laser processing plays a critical role in shaping the highly reactive LiM material for the required battery configuration. Politecnico di Milano (POLIMI), through its SITEC - Laboratory for Laser Applications of the Department of Mechanical Engineering, led by Prof. Ali Gökhan Demir, will develop a precision laser micro-cutting process for LiM anodes. Given the extreme sensitivity of LiM to environmental conditions and energy input, SITEC will test a comprehensive range of laser sources—from continuous wave (CW) to nanosecond and ultrafast pulsed lasers—operating under controlled atmosphere. This approach will allow for precise tailoring of laser parameters to ensure high-quality cuts while avoiding material degradation, ensuring both safety and manufacturability.

To enhance process control, STELLAR will develop a real-time digital twin (DT) to model, monitor, and optimise the entire production chain. In parallel, the project adopts a circular economy strategy to improve the recyclability of materials and maximise lithium recovery at battery end-of-life, thus contributing to sustainability and resource efficiency across the battery lifecycle.

The STELLAR consortium comprises 16 partners from 7 EU countries, ensuring expertise across the full value chain. It includes:

- 8 industrial and SME partners - AVESTA (coordinator), AGC, COMAU, AVESTA, HSSMI and others - who bring manufacturing capabilities, equipment development, and market-driven insight;

- 7 academic and research institutions - CSEM, CID, CEIT, IKERLAN, Fraunhofer, UNITO, and POLIMI - offering expertise in materials science, battery engineering, laser applications, digital modelling, and sustainability;

- 1 dissemination and communication expert - INOVA+, supporting outreach, exploitation, and stakeholder engagement.

The project is committed to open science, gender equality, and public engagement, with all partners actively supporting inclusive research practices and broader societal impact. STELLAR will also collaborate with an Industrial Advisory Board (IAB) and coordinate with major EU initiatives like BATTERY 2030+ to ensure alignment with strategic objectives and accelerate industrial uptake.

By the end of the project, STELLAR aims to reach Technology Readiness Level 7 (TRL7) through a first-of-its-kind, EU-based pilot line for LiM anode production, validated in real battery cells—positioning Europe at the forefront of sustainable battery manufacturing.