Bioprinting is a multidisciplinary research field combining state-of-the-art technologies from additive manufacturing, biology and material sciences to create living tissues. The interest towards the possibility of reproducing bioconstructs with geometries and functions that mimic living tissues ones is boosted by the ever-increasing need for personalized medicine, one of the main medical objectives of the society of the future.

Thus, within the actual biomedical research context, bioprinting is gaining increasing attention from companies, universities, and research institutes. Scientific literature in this field is exponentially increasing, and also the Politecnico di Milano is bringing its contribution to the growth of this sector. For this purpose has been established a new collaboration between the Mechanical Engineering Department and the Chemical Engineering Department, with the joint “3D Cell Lab” co-founded by Proff. Bianca Maria Colosimo and Davide Moscatelli.

The main applications of 3D bioprinting can be found in cell biology research, in the production of tissue models for drug testing and in the field of regenerative medicine for future replacement of tissues and organs for fighting the donor organ shortage.

Interest in 3D bioprinting has been gaining momentum in recent years not only in the academia but also in the market. Numerous 3D bioprinting companies are welcoming the market as well as start-ups, spin-offs and subsidiaries. The patent literature is exploding and new technologies and innovative biomaterials suitable for bioprinting are becoming more and more widespread.

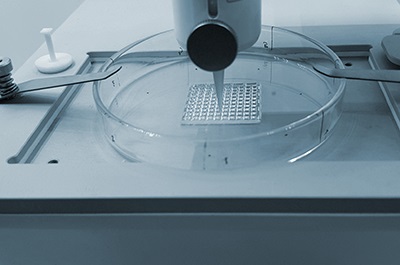

Bioprinting could become a new paradigm for the biofabrication of tissues and the Politecnico di Milano has adopted all the major technologies currently available to keep up: technologies based on nozzle-deposition for extrusion-based and inkjet-based bioprinting, and technologies based on vat photopolymerization processes. Regarding the last class of optical-based technologies, the Politecnico di Milano, in collaboration with Lombardy region, is about to install one of the first bioprinter with micrometric resolution and high speed based on two-photon polymerization printing process to create a new generation of vascularized tissues to allow cell survival in any location of the bioprinted construct.

Within the project, thanks to the transfer of knowledge gained in the additive manufacturing field, the Mechanical Engineering Department will be in charge of developing new solutions for in-situ data sensing, process optimization monitoring and control fostering the convergence between manufacturing, big data mining for biomedical research.

Research activities will be also adjuvanted by the Chemical Engineering Department, which will explore the possibility of studying innovative biomaterials.

With the results obtained, the Politecnico di Milano will be able to contribute to research proposing new methods and solutions for producing a new generation of vascularized bioprinted tissues which will boost research in this area.