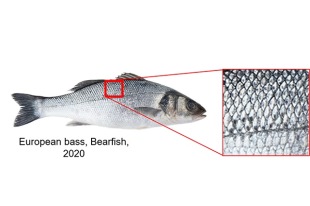

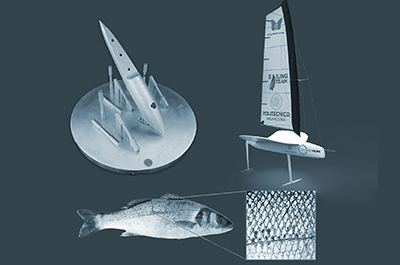

DMEC researchers developed a novel solution for producing biomimetic surface textures - inspired by the European bass - on Al-alloy components. Project Levrek (Levrek is the Turkish name of the European Bass) aims to mimic the scales of the European bass on a rudder bulb designed for the sailing boat for the Polimi Sailing Team. The objective of the project is to improve the structural features of the component, reducing its weight using additive manufacturing (AM) technique, taking the chance also to improve the fluid-dynamic features by texturing its surface. The researchers modelled the natural features of the fish in a digital environment, carried out a parametric analysis with computational fluid dynamics (CFD) approach to assess its performance and choose the most efficient scale proportions.

After undergoing a topology optimization phase and being produced by laser powder bed fusion, a layer-by-layer additive manufacturing (AM) technique, the designed metallic scales were applied on a rudder bulb. These research activities perfectly meets the objectives of the Departments of Excellence in the LIS4.0 project, where the focus is on Lightweight and Smart structures.

The research required a multidisciplinary team composed by Sailing, CFD and AM experts. Alessandro Scarpellini, the leader of Polimi Sailing Team worked together with Dr. Paolo Schito and Prof. Ali Gökhan Demir. For the innovative design, a first study on the hydrodynamics of European Bass scales was conducted, identifying the most promising scale dimension that reduces the rudder bulb fluid-dynamic resistance. The researchers modelled the fish scales in a 3D computer aided design environment first. Different scale dimensions were tested using CFD within the opensource framework OpenFOAM on the High-Performance Computer (HPC) infrastructure CFDHub: the researchers discovered the most suitable dimensions as well as the influence of surface roughness and the sail speed. Then the focus was on the realization of the component: laser powder bed fusion was chosen as metal additive manufacturing process and the material is AlSi7Mg0.6 alloy. The rudder bulb was then topologically optimized to reduce the weight of the component. The chosen fish scale was integrated to the surface of the bulb. Finally, the component was produced by a Trumpf TruPrint 3000 at AddMe.Lab. The produced rudder bulb is one of the first of its kind incorporating bioinspired surfaces and topological optimization in a metallic component.

For the naval applications, the novel findings can open new possibilities for improving the sailing performance, but also for reducing material usage. The initial findings of the research has been peer-reviewed and published (J. Mar. Sci. Eng. 2021, 9(9), 1032). The innovativeness of the work has also been appreciated by the industry as Alessandro Scarpellini was awarded the UCIMU Thesis Prize by the Italian Machine Tool, Robots, Automation Systems and Ancillary Products Manufacturers' Association.